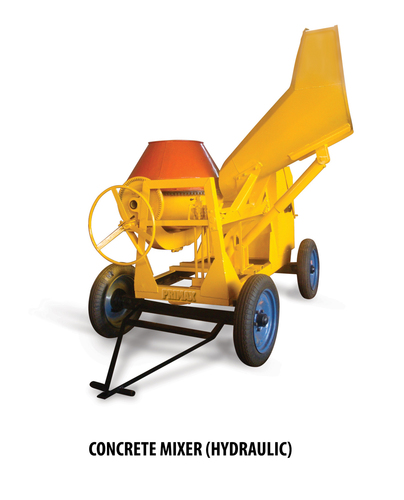

Hydraulic Hopper Concrete Mixer

Price 450000.00 INR/ Piece

Hydraulic Hopper Concrete Mixer Specification

- Lifting Height

- Up to 30 meters

- Motor Power

- 5 HP Electric Motor or 6.5 HP Diesel Engine

- Surface

- Paint Coated

- Lifting Speed

- 12-18 m/min

- Product Type

- Hydraulic Hopper Concrete Mixer

- General Use

- Mixing and lifting concrete for construction

- Material

- Heavy Duty Steel

- Type

- Hopper Type Concrete Mixer

- Capacity

- 10/7 CFT (cubic feet)

- Weight (kg)

- ~1650 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Manual Lever/Control Panel

- Cooling System

- Air Cooled

- Method

- Hydraulic Hopper Lifting

- Voltage

- 415 V (for electric type)

- Dimension (L*W*H)

- 2600 mm x 1500 mm x 2100 mm

- Feature

- Heavy-duty, easy mobility, efficient mixing, sturdy hopper design

- Color

- Yellow or as per requirement

- Drum Speed

- 20 - 22 RPM

- Operator Required

- Single operator

- Safety Feature

- Reverse drum lock, mechanical brake

- Lubrication System

- Grease cup lubrication

- Chassis Type

- Heavy duty, rigid steel

- Engine Type (Optional)

- Air-cooled diesel

- Mobility

- Towable trolley frame with hitch

- Noise Level

- Less than 80 dB

- Hopper Operation

- Hydraulic cylinder powered

- Batch Mixing Time

- 2-3 minutes

- Discharge

- Tilting drum discharge

- Water Tank Capacity

- 120 liters (approx.)

- Wheels

- Four pneumatic tyred wheels

- Mixing Drum Material

- M.S. (Mild Steel) Plate

Hydraulic Hopper Concrete Mixer Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Year

- Delivery Time

- 1 Week

- Main Domestic Market

- East India

- Certifications

- ISO 9001:2008

About Hydraulic Hopper Concrete Mixer

Hydraulic Hopper Concrete Mixer is designed with durable bag concrete mixer to mix cement, sand as well as other aggregates for making cement of the required grade. This is designed with digital accurate load cell based weighing system along with double bin hydraulically operated hopper. It comes with automatic water pump and tyre axle with locking system to ensure unmatched efficacy. In addition, this Hydraulic Hopper Concrete Mixer is available with heavy duty cast iron drum for easy tilting of drum.

PRIMAX (P-7) Hydraulic operted Hopper-fed tilting drum type Concrete Mixer, Capacity 10/7 cft, operated by 6 HP Air-cooled Diesel Engine/5 HP Electric Motor.

Sturdy Construction and Efficient Performance

Built with high-quality mild steel and a rigid chassis, this hopper mixer ensures long-lasting performance for heavy-duty applications. The semi-automatic system is designed for efficient mixing and quick batch turnover, while the hydraulic hopper minimizes operator fatigue and enhances safety. Four pneumatic wheels and a towable frame enable easy transport across construction sites.

User-Friendly and Versatile Functionality

Operation is simple, requiring just one operator, thanks to manual levers or a control panel. The mixer offers lifting speeds of 1218 meters per minute and can lift concrete up to 30 meters, streamlining the pouring process for multi-storey construction. The noise level remains below 80 dB, making it suitable for urban environments as well.

FAQs of Hydraulic Hopper Concrete Mixer:

Q: How does the hydraulic hopper mechanism work in this concrete mixer?

A: The hydraulic hopper of the mixer uses a hydraulic cylinder to lift and lower the hopper, making it easy to load aggregates into the mixing drum. This mechanism reduces manual effort, speeds up the batching process, and enhances operator safety.Q: What are the main safety features included with this mixer?

A: The mixer is equipped with a reverse drum lock and a mechanical brake system, which prevent accidental drum reversal and unintentional movement during operation. These features, combined with the heavy-duty, rigid chassis, provide a safe working environment.Q: When is this concrete mixer ideal for use on construction sites?

A: This mixer is particularly useful for projects requiring frequent mixing and lifting of concrete, such as multi-story buildings or large-scale foundation works. Its rapid batch mixing and high lifting height enable efficient concrete distribution across vertical structures.Q: Where can this mixer be conveniently used or transported?

A: With its four pneumatic tyred wheels and towable trolley frame, the mixer can be easily transported and maneuvered across rough or uneven site terrains. Its compact dimensions also allow for effective use in both urban and rural project locations.Q: What is the process for operating the mixer?

A: Operation involves loading materials into the hopper, using the manual lever or control panel to activate the hydraulic lift, and starting the mixing drum (powered by either an electric motor or diesel engine). Once mixed, concrete is discharged by tilting the drum, and the process can be repeated efficiently.Q: How is maintenance handled for this concrete mixer?

A: Maintenance is straightforward due to the grease cup lubrication system, which ensures smooth operation of moving parts. Periodic checks of the hydraulic system, drum, and safety mechanisms are recommended to prolong the mixers lifespan.Q: What are the benefits of choosing this semi-automatic hydraulic hopper mixer?

A: Users benefit from efficient mixing, ease of operation by a single worker, and excellent mobility. The hydraulic hopper speeds up workflow and reduces strain on operators, while the mixers durable design ensures it withstands intensive, regular use on construction sites.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Mixer Category

Mechanical Hopper Concrete Mixer

Price 450000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Mechanical Hopper Type

Weight (kg) : Approx. 15001600 kg

Feature : Heavy Duty Drum, Sturdy Chassis, Easy Mobility

Cooling System : Other, Air Cooled (Diesel Engine)

Hydraulic Concrete Mixer

Price 450000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Hydraulic Hopper

Weight (kg) : 1100 kg

Feature : Portable, easy to operate, low maintenance

Cooling System : Other, Air cooled

3 bag mixer

Price 725000.0 INR / Piece

Minimum Order Quantity : 1 Number

Weight (kg) : 12001500 kg (approx.) Kilograms (kg)

Feature : Self Loading, Easy Transport, High Mobility

Cooling System : Other

Tilting Hopper Fed Concrete Mixer

Type : Other, Tilting Type

Weight (kg) : Approximately 400 Kg

Feature : Tilting Hopper for concrete feeding

Cooling System : Air Cooled, Other

Send Inquiry

Send Inquiry