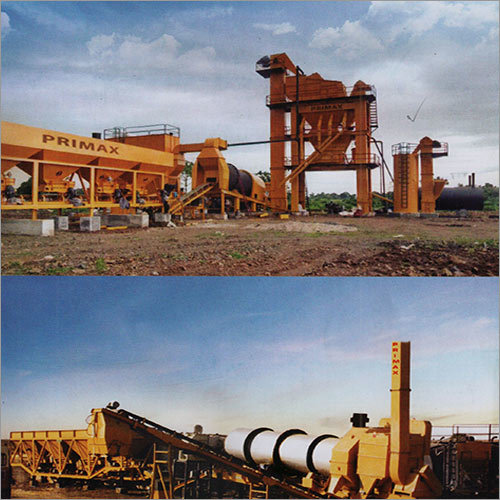

Asphalt Mixing Plant

Price 350000.00 INR/ Piece

Asphalt Mixing Plant Specification

- Type

- Asphalt Mixers

- Material

- Iron

- Computerized

- No

- Automatic Grade

- Manual

- Cooling System

- Frequency Speed Control

Asphalt Mixing Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- KOLKATA

- Supply Ability

- 1 Piece Per Year

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- Meghalaya, Andaman and Nicobar Islands, East India, Daman and Diu, Nagaland, West Bengal, Uttar Pradesh, Tripura, Jharkhand, Mizoram, Odisha, Bihar, Chhattisgarh, Sikkim, Assam, Manipur, Arunachal Pradesh

- Certifications

- ISO2008-2015

About Asphalt Mixing Plant

Asphalt Mixing Plant offered to you by our company is manufactured using best quality raw materials and upgraded technology under the supervision of experienced professionals. This plant is used for mixing the dry warm aggregate, padding as well as asphalt for homogeneous mixture at the required temperature. This is widely used for the construction of highways, roads, and parking lots. Asphalt Mixing Plant is known for its high efficiency, good strength, better accuracy, thermally insulated drying drum, easy transportation as well as fast installation, extended service life, seamless structure and best performance. This system comprises of multi fuel burner for the drying and mixing drum for mixing. This system is very economical as it requires comparatively low maintenance and operating costs.

Features

- Advanced modular design, modern and compact in structure for easy relocation and erection.

- Specially designed dryer drum and blade arrangement with high heat efficiency.

- The high pressure atomized burner of reputed make for fuel efficiency and high safety standard.

- Initial mixer of cold aggregates through the speed adjustable belt feeder, easy and accurate in adjustment.

- High efficiency vibrating screen minimise vibrating impact on frame structure.

- All electronic weighing sensor with high accuracy and reliability

- New type horizontal twin shaft mixer with ability to produce fast and high quality homogenous mix.

- Modern user friendly computer management control system with data storage, reports printing, malfunction and alarm monitoring system.

Technical Specifications

| Plant model | | | PBP 1500 | PBP 2000 |

| | Plant capacity @3% moisture content | Tph | 90-120 | 120-160 |

| | Batch size | Kg | 1500 | 2000 |

| | Cycle time | Sec | 45 | 45 |

| Units | | | | |

| Cold feed bins | No. of bins/capacity | Nos/m3 | 4/25 | 4/30 |

| Charging conveyor | Capacity | Tph | 140 | 180 |

| Thermo drum | Dryer (LXD) | Mtrs | 7.5x1.8 | 8x2.1 |

| | Drive type | | 4w chain drive | |

| Burner | Type | | High pressure, fully automatic, modulating | |

| | Fuel | | Diesel/Furnace oil | |

| | Capacity | MW/hr | 14.1 | 14.1 |

| Hot elevator | Capacity | Tph | 140 | 180 |

| Tower unit | | | | |

| Screen unit | Screening method | | Inclined circular vibration | |

| | No. of deck | | 4 | 4 |

| | Screening capacity | Tph | 140 | 180 |

| Hot aggregate bin unti | No. of bins | | 4 | 4 |

| Weighing unit | Aggregate hopper capacity | Kg | 1500 | 2000 |

| | Filler hopper capacity | Kg | 300 | 300 |

| | Bitumen hopper capacity | Kg | 200 | 200 |

| Mixer unit | Type | | Twin shaft hot oil jacketed | |

| | Mixer capacity | Kg | 1500 | 2000 |

| | Bitumen pump | Lpm | 800 | 800 |

| Pollution control unit | | | | |

| Primary | Type | | Centrifugal cyclone | |

| Secondary | Type | | Bag house filter | |

| | Bag house filter | | Reverse air flow | |

| | Filter area | M2 | 330 | 330 |

| Control panel | Type | | Fully computerized with manual over-ride | |

| Accessories | | | | |

| Filler hoppe/screw | Capacity range | M3 | Optional as per customer requirement | |

| Bitumen tanks | Capacity range | Ton | 30/50 | |

| | Heating system | | Direct heating/Thermic oil heating | |

| Thermic oil heater | Hot oil heater capacity | Kcal/hr | 500000 | |

Manual Efficiency with Precision

Our Asphalt Mixing Plant operates without computerized componentsgiving operators manual control over the mixing process. This design enables tailored adjustments, ensuring you achieve the desired mix characteristics for your specific projects without the complexity of automated systems. Built with iron, the plant excels in durability and reliability, offering you a blend of traditional control and modern performance.

Advanced Cooling with Frequency Speed Control

Equipped with a frequency speed control cooling system, this asphalt mixer maintains optimal material temperatures throughout the mixing process. By accurately managing cooling rates, the system reduces thermal stress, improves mixture uniformity, and extends equipment life. This innovation supports high-quality asphalt production even in variable operating conditions.

FAQs of Asphalt Mixing Plant:

Q: How do you operate the manual asphalt mixing plant?

A: The plant is operated through manual controls, allowing the user to adjust mixing speeds, material input, and temperature management. This hands-on approach provides flexibility to make on-the-spot decisions during the mixing process, ensuring precise results based on project requirements.Q: What are the main benefits of a non-computerized asphalt mixer?

A: A non-computerized mixer eliminates dependency on complex electronics and software, which reduces maintenance requirements and potential downtime. Operators benefit from straightforward controls, making the equipment ideal for environments with limited access to technical support.Q: When should you choose a manual asphalt mixing plant over an automated one?

A: Manual plants are best suited for smaller projects or sites where budget constraints make full automation impractical. They also fit scenarios requiring customized mixes or locations with unpredictable power supply, given their reduced reliance on sensitive electronic components.Q: Where can this asphalt mixer be deployed?

A: This plant is suitable for construction sites across India and can be installed in both urban and rural locations. Its durable iron construction and manual controls make it adaptable to diverse environments and challenging conditions.Q: What is the process of mixing asphalt with this plant?

A: The process involves manually loading raw materials, adjusting mixing speeds, and closely monitoring temperatures via the frequency speed control system. Operators can fine-tune these variables in real-time to ensure a homogeneous and high-quality asphalt batch every cycle.Q: How does frequency speed control enhance the cooling system?

A: The frequency speed control enables precise management of cooling rates, allowing operators to adapt the process according to material and environmental changes. This results in consistent asphalt temperature and quality, minimizing issues such as aggregate segregation or premature hardening.Q: What advantages does the iron construction provide?

A: Manufacturing the mixer with iron ensures excellent structural strength and longevity. This robust material withstands heavy-duty use, frequent transportation, and variable weather, making the plant a reliable investment for long-term asphalt production needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Road Construction Machinery Category

Wet Mix Macadam Plant

Price 350000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Cooling System : Other, Air Cooling

Color : Blue/Yellow/As per order

Computerized : No

Automatic Grade : SemiAutomatic

Catonic Sprayer

Price 350000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Cooling System : Other, Air Cooled

Color : Silver/Blue

Computerized : No

Automatic Grade : SemiAutomatic

Mobile Wet Mix Macadam Plant

Cooling System : Air Cooling, Other

Color : Yellow

Computerized : Yes

Automatic Grade : Automatic

Oil Fired Tar Bitumen Boiler

Minimum Order Quantity : 1 Unit

Cooling System : Human Machine Interface

Color : Yeloow

Computerized : No

Automatic Grade : SemiAutomatic

Send Inquiry

Send Inquiry