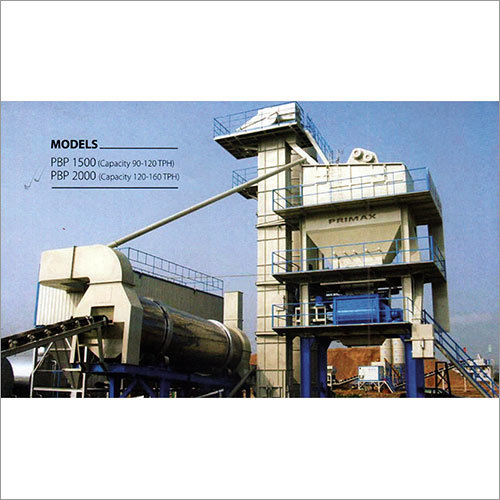

Primax Asphalt Mixing Plant

Price 20000000 - 25000000 INR/ Piece

Primax Asphalt Mixing Plant Specification

- Product Type

- Asphalt Mixing Plant

- General Use

- Suitable for mixing asphalt for road construction

- Material

- Mild Steel

- Weight (kg)

- Heavy Duty (Approx. 8000 kg)

- Computerized

- Optional

- Automatic

- Semi-Automatic

- Control System

- Panel Control

- Power Source

- Electric

- Power Consumption

- 55 kW

- Storage Capacity

- Up to 40 Tons

- Hopper Capacity

- 2500 kg

- Hopper Quantity

- 4

- Conveyor Capacity

- 30 Tons/hr

- Mixing Drum Speed

- 18-22 rpm

- Discharging Height

- 3.8 m

- Voltage

- 440 V

- Dimension (L*W*H)

- 11m x 2.5m x 3.8m

- Feature

- High Performance, Sturdy Construction, Energy Efficient

- Color

- Blue / Yellow

- Connectivity

- Manual and PLC Option Available

- Warranty Coverage

- On-site Service Included

- Drive System

- Heavy Duty Gearbox

- Fuel Type

- Diesel / Furnace Oil

- Aggregate Size

- Up to 60 mm

- Burner Type

- Automatic Modulated Burner

- Rated Output

- 40-60 tons/hr

- Drum Material

- Hard-wearing Steel

- Mobility

- Stationary / Wheel Mounted options available

- Operating Temperature

- Up to 160°C

- Dust Collector

- Multi Cyclone with separate bag filter

- Overload Protection

- Available

- Greasing System

- Automatic Centralized Greasing

- Drying Drum Length

- 6.5 m

Primax Asphalt Mixing Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- KOLKATA

- Payment Terms

- Cash Against Delivery (CAD), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Open

- Main Export Market(s)

- Asia

- Main Domestic Market

- Tripura, Manipur, Nagaland, Andhra Pradesh, Jharkhand, West Bengal, Uttar Pradesh, Telangana, Andaman and Nicobar Islands, Odisha, Bihar, Mizoram, Sikkim, Meghalaya, Arunachal Pradesh, Assam, Chhattisgarh

- Certifications

- ISO 9001:2015

About Primax Asphalt Mixing Plant

Primax Asphalt Mixing Plant

Asphalt Mixing Plant is an advanced industrial unit which is equipped with high performance electrically powered machineries that helps to produce large volume of hot asphaltic mixture which can be used for the construction of roads and highways. It is highly demanding due to its large production capacity in between 90 to 160 ton per hour and low maintenance cost. It is also provided with a drying unit which helps to minimize the moisture content from the raw materials.

Feature of Primax Asphalt Mixing Plant:

- Advanced modular design, modern and compact in structure for easy relocation and erection.

- Specially designed dryer drum and blade arrangement with high heat efficiency.

- The high pressure atomized burner of reputed make for fuel efficiency and high safety standard.

- Initial mixer of cold aggregates through the speed adjustable belt feeder, easy and accurate in adjustment.

- High efficiency vibrating screen minimise vibrating impact on frame structure.

- All electronic weighing sensor with high accuracy and reliability

- New type horizontal twin shaft mixer with ability to produce fast and high quality homogenous mix.

- Modern user friendly computer management control system with data storage, reports printing, malfunction and alarm monitoring system.

Technical Specifications

| Plant model | | | PBP 1500 | PBP 2000 |

| | Plant capacity @3% moisture content | Tph | 90-120 | 120-160 |

| | Batch size | Kg | 1500 | 2000 |

| | Cycle time | Sec | 45 | 45 |

| Units | | | | |

| Cold feed bins | No. of bins/capacity | Nos/m3 | 4/25 | 4/30 |

| Charging conveyor | Capacity | Tph | 140 | 180 |

| Thermo drum | Dryer (LXD) | Mtrs | 7.5x1.8 | 8x2.1 |

| | Drive type | | 4w chain drive | |

| Burner | Type | | High pressure, fully automatic, modulating | |

| | Fuel | | Diesel/Furnace oil | |

| | Capacity | MW/hr | 14.1 | 14.1 |

| Hot elevator | Capacity | Tph | 140 | 180 |

| Tower unit | | | | |

| Screen unit | Screening method | | Inclined circular vibration | |

| | No. of deck | | 4 | 4 |

| | Screening capacity | Tph | 140 | 180 |

| Hot aggregate bin unti | No. of bins | | 4 | 4 |

| Weighing unit | Aggregate hopper capacity | Kg | 1500 | 2000 |

| | Filler hopper capacity | Kg | 300 | 300 |

| | Bitumen hopper capacity | Kg | 200 | 200 |

| Mixer unit | Type | | Twin shaft hot oil jacketed | |

| | Mixer capacity | Kg | 1500 | 2000 |

| | Bitumen pump | Lpm | 800 | 800 |

| Pollution control unit | | | | |

| Primary | Type | | Centrifugal cyclone | |

| Secondary | Type | | Bag house filter | |

| | Bag house filter | | Reverse air flow | |

| | Filter area | M2 | 330 | 330 |

| Control panel | Type | | Fully computerized with manual over-ride | |

| Accessories | | | | |

| Filler hoppe/screw | Capacity range | M3 | Optional as per customer requirement | |

| Bitumen tanks | Capacity range | Ton | 30/50 | |

| | Heating system | | Direct heating/Thermic oil heating | |

| Thermic oil heater | Hot oil heater capacity | Kcal/hr | 500000 | |

High-Performance Output

Designed for productivity, the Primax Asphalt Mixing Plant delivers 40-60 tons of asphalt per hour. Its heavy-duty gearbox and sturdy construction allow it to maintain consistent operation even during intensive road-building projects. With a drying drum length of 6.5 meters and a mixing speed of 18-22 rpm, it ensures thorough, high-quality mixing of aggregates up to 60 mm.

Advanced Control and Safety Features

The asphalt plant incorporates both PLC and manual control options, giving operators the flexibility to choose their preferred method of operation. Safety is enhanced with overload protection and automated centralized greasing, while the multi-cyclone dust collector with bag filter keeps emissions under control, contributing to a cleaner worksite environment.

Versatile and Convenient Design

Available in both stationary and mobile formats, the Primax plant adapts to a variety of project requirements. Its 4 hoppers, 40-ton storage, and 2500 kg hopper capacity ensure efficient material management. Automated features and energy-efficient operation (55 kW power consumption) promote ease of use and cost savings over the lifetime of the equipment.

FAQs of Primax Asphalt Mixing Plant:

Q: How does the Primax Asphalt Mixing Plant ensure efficient asphalt production?

A: This plants automatic modulated burner, heavy-duty gearbox, and advanced control systems maintain consistent mixing and temperature (up to 160C), producing 40-60 tons of asphalt per hour while ensuring uniform quality.Q: What types of fuel can be used with this asphalt mixing plant?

A: The Primax plant is compatible with both diesel and furnace oil, providing fuel flexibility based on availability and cost considerations for different project sites.Q: When is the stationary versus wheel-mounted option most beneficial?

A: Stationary units are ideal for long-term, large-scale projects at a fixed location, while the wheel-mounted version provides mobility, making it perfect for contractors who shift between multiple job sites.Q: Where is the dust collected during the mixing process?

A: Dust generated during making is captured by a multi-cyclone system with a separate bag filter, ensuring environmental compliance and a cleaner operational area.Q: What is the process for routine maintenance of the Primax plant?

A: The included automatic centralized greasing system simplifies day-to-day lubrication of essential parts, while on-site service under warranty aids in scheduled inspections and timely repairs, preserving operational efficiency.Q: How does the plant support energy efficiency and environmental responsibility?

A: Its energy-saving design, automatic controls, and dust collection system minimize power consumption and emissions, supporting both sustainability and lower operating costs.Q: What benefits does the automatic centralized greasing system provide?

A: This system reduces the risk of mechanical failures, decreases maintenance downtime, and extends the lifespan of key moving components, enhancing overall plant reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry