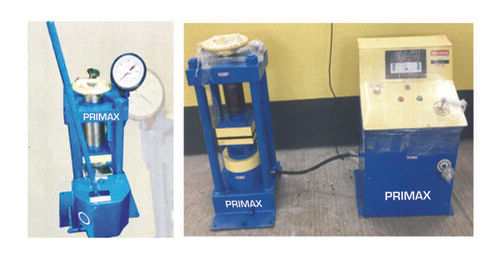

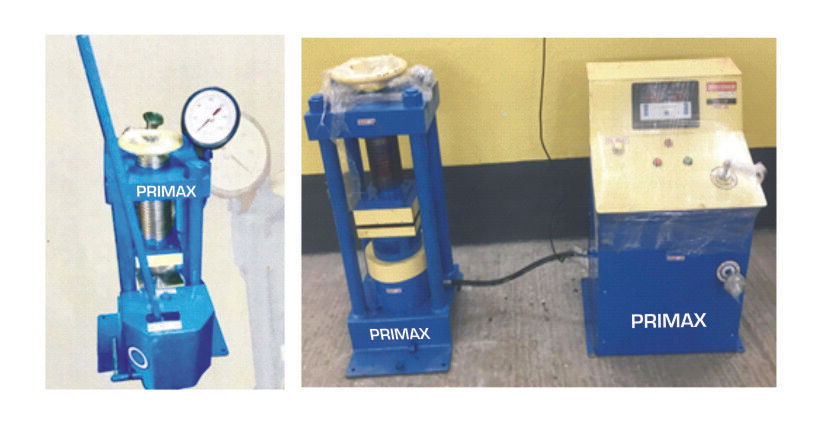

Compression Testing Machine

Compression Testing Machine Specification

- Product Type

- Compression Testing Machine

- General Use

- Industrial

- Material

- Steel

- Automatic

- Yes

- Control System

- Manual

- Feature

- High Quality

Compression Testing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About Compression Testing Machine

Compression Testing Machine

Compression Testing Machine is an industrial grade test instrument which is use for the determining the strength of the specimen under consideration by applying large compressive forces with the help of vertically moving hydraulic ram which can be controlled with the help of an easy to use electric control panel. The base frame of this unit is fabricated by using heavy engineering grade mild steel that makes it capable to withstand large impact forces.

Reliable and Accurate Compression Testing

Experience stress-free material analysis with our high-quality Compression Testing Machine. Built from durable steel and equipped with a user-friendly manual control system, this automatic device brings precise, repeatable results, making it a staple for manufacturers, suppliers, and exporters. Its robust construction and advanced features are tailored to meet the varied demands of industrial environments in India.

Perfect Solution for Industrial Needs

Our Compression Testing Machine stands out in the industrial equipment market for its strong build, accurate data output, and adaptability for rigorous applications. Exporters, manufacturers, and suppliers seeking to verify material integrity will find this device indispensable for ensuring product reliability and compliance with industry standards.

FAQs of Compression Testing Machine:

Q: How does the manual control system work on this compression testing machine?

A: The manual control system allows operators to adjust load application and monitor results directly, offering hands-on control for precise compression testing. This helps users maintain accuracy, especially important in industrial environments where material properties vary.Q: What materials can be tested using this machine?

A: This machine is primarily designed for steel but is versatile enough to accommodate various other construction and industrial materials. Its strong frame and high-quality components ensure reliable performance across multiple material types.Q: When should you conduct compression tests with this machine?

A: Compression tests should be carried out during material inspection, quality control, or developmental phases of industrial projects. Regular testing ensures materials meet required standards before being used in manufacturing, construction, or export.Q: Where is this compression testing machine commonly used?

A: It is widely used in industrial labs, quality assurance departments of manufacturing plants, and supplier testing facilities across India. Its robust design and high accuracy make it suitable for both in-house and third-party testing environments.Q: What is the process for performing a compression test using this machine?

A: First, the test specimen is placed on the machines platform. Using the manual controls, the load is gradually applied until the material fails or the desired data point is reached. The machine records force and deformation values for analysis.Q: How does this equipment benefit exporters and manufacturers in India?

A: Exporters and manufacturers benefit through improved product reliability, conformance to quality standards, enhanced market reputation, and reduced risk of material failure. Accurate compression testing allows for trusted certification and global competitiveness.Q: What makes this compression testing machine high quality?

A: High-grade steel construction, precision engineering, and the integration of a manual control system combine to offer excellent durability and repeatable accuracy. Strict quality standards during manufacturing assure consistency and long machine life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Construction Machinery Category

Concrete Mixer With Lift (Hoist)

Minimum Order Quantity : 1 Piece

Computerized : No

Control System : Other, Manual lever operated

Feature : Easy to operate, robust structure, efficient lifting mechanism

Product Type : Concrete Mixer With Lift (Hoist)

Vibrating Plate Compactor

Price 450000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Control System : Other, Manual handle control

Feature : Heavyduty base, high compaction force, easy mobility

Product Type : Vibrating Plate Compactor

Concrete Cube Mould

Price 450000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Control System : Manual

Feature : Rigid construction, High dimensional accuracy, Reusable

Product Type : Mould

Mobile Batching Plant With Pan Type Mixer

Computerized : No

Control System : Other, PLC Control Panel

Feature : Portable, Easy Installation, Robust Design

Product Type : Mobile Batching Plant With Pan Type Mixer

Send Inquiry

Send Inquiry