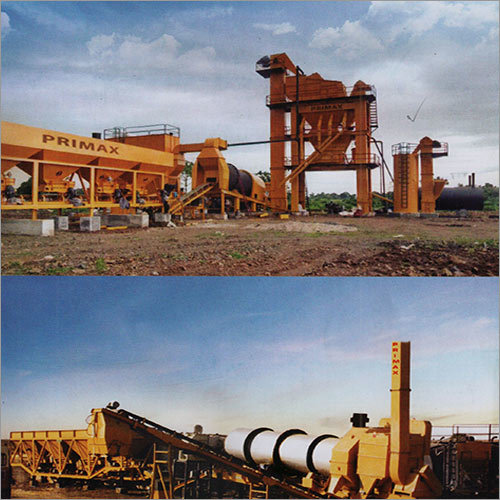

Mobile Hot Mix Plant With Pugmill System

Price 350000.00 INR/ Piece

Mobile Hot Mix Plant With Pugmill System Specification

- Noise Level

- Below 80 dB

- Mount Type

- Mobile, Wheel Mounted

- Temperature

- 130C to 165C

- Air Pressure

- 6-8 kg/cm

- Driven Type

- Diesel Engine Driven

- Fuel Type

- Diesel

- Hopper Capacity

- 2 x 1.5 m

- Compressor Type

- Reciprocating Air Compressor

- Hole Size

- 45 mm

- Tank Dimensions (Mm X Mm X Mm)

- 3200 x 2400 x 2200 mm

- Tank Material

- Mild Steel

- Coverage Area

- 75 sq.m.

- Working Width

- 2400 mm

- Type

- Mobile Hot Mix Plant with Pugmill System

- Material

- Heavy-duty Steel Structure

- Capacity

- 40 to 60 TPH (tons per hour)

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Cooling System

- Air Cooled

- Vibration Frequency

- 50 Hz

- Drum Diameter

- 1.2 m

- Power

- 125 HP

- Size

- Medium

- Color

- Yellow-Black

- Weight

- 8500 kg

- Dimension (L*W*H)

- 9800 x 2400 x 3300 mm

Mobile Hot Mix Plant With Pugmill System Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- kolkata

- Supply Ability

- 1 Piece Per Year

- Delivery Time

- 1 Week

- Main Domestic Market

- East India

- Certifications

- ISO 9001:2008

About Mobile Hot Mix Plant With Pugmill System

PRIMAX Mobile Hot Mix Plant is a separate drying & mixing system. Capacity - 6/10 TPH & 10/16 TPH. The whole unit is mounted on a strong heavy chassis with pneumatic tyre wheels and drawbar turntable for easy towing. Foldable feed elevator and chimney along with an efficient dust collector, special type of oil burner are provided.

Large diameter storage ring at discharge end of the dryer drum for holding hot aggregates. The drum runs of 4 nos. C.I. rollers with bearings. Mixing unit consist of twin shaft Pugmill, heavy duty paddle arms and tips. The dryer is driven through reduction gear and chain drives. The plant is powered by adequate rated diesel engine.

Optional Extras Include:

- Built-in integrated Bitumen Boiler of 1000 litres capacity with bitumen pump.

- Mechanical Telescopic Jack to increase discharge height (Hot mix).

- Front Loading arrangement enabling working width to be retained within the width of the machine.

Capacity: 6/10 TPH & 10/16 TPH.

Efficient Aggregate Management

The plant features a four-bin aggregate feeder equipped with adjustable gates, allowing precise control over material flow. This setup ensures consistent aggregate blending, essential for producing high-quality hot mix asphalt. The inclusion of a belt conveyor further supports smooth movement of materials to the Pugmill Mixer, optimizing the overall efficiency of the mixing process and reducing manual intervention.

Advanced Pugmill Mixing Technology

With a mixer capacity of 2.2 m and a 45-second mixing cycle, the Pugmill system ensures rapid and thorough blending of components. This results in uniform output material ranging from 0 to 40 mm in size. The automatic pressure jet burner maintains the required temperature between 130C to 165C, promoting seamless bitumen integration and consistent mixture quality throughout each batch.

Robust Safety and Emission Controls

Operator safety and environmental protection are prioritized through the inclusion of an emergency stop switch and a dust collecting system. These features reduce airborne particles and enable swift cessation of operations in case of emergency. The user-friendly weather-proof control panel enhances ease of operation while maintaining resilience against harsh outdoor conditions.

Mobile Design for Flexible Deployment

Mounted on wheels with a towing bar and supported by a sturdy single axle chassis, the plant is engineered for mobility. It can be easily transported between sites and set up with minimal effort. This adaptability makes it ideal for a wide range of road construction projects, offering ample coverage area and effective operation in diverse locations.

FAQs of Mobile Hot Mix Plant With Pugmill System:

Q: How does the four-bin aggregate feeder improve mixing quality?

A: The four-bin aggregate feeder with adjustable gates allows precise proportioning of different aggregates, ensuring accurate blending before entering the Pugmill Mixer. This results in enhanced consistency and quality of the final hot mix asphalt product.Q: What is the process for operating the Mobile Hot Mix Plant with Pugmill System?

A: Operation involves feeding aggregates through the four-bin feeder, transferring them via the belt conveyor to the Pugmill Mixer where bitumen is also added. The automatic pressure jet burner heats the mix to the required temperature, and after a 45-second cycle, the finished material is discharged at a height of 3.1 meters.Q: When is the Mobile Hot Mix Plant most effectively used?

A: This plant is best suited for road construction and repair projects requiring onsite production of hot mix asphalt, particularly when mobility and rapid setup are essential. It efficiently handles medium-scale operations with a capacity of 40 to 60 TPH.Q: Where can the plant be deployed and what is its coverage area?

A: Thanks to its wheel-mounted design and towing bar, the plant can be easily relocated and deployed at various construction sites. It covers an operational area of approximately 75 square meters, supporting efficient workflow in diverse environments.Q: What safety features are built into the system?

A: Safety is ensured by the inclusion of an emergency stop switch on the control panel, allowing for quick shutdown in critical situations. The dust collecting system further enhances operational safety by minimizing airborne particulate emissions.Q: How does the emission control system benefit environmental compliance?

A: The fitted dust collecting system captures and reduces particulate emissions during the mixing process, helping the plant comply with strict environmental standards and lowering the environmental footprint of road construction activities.Q: What are the advantages of the plants mobile and robust design?

A: Its sturdy single axle chassis, heavy-duty steel structure, and wheel-mounted mobility enable easy transport and onsite setup. This flexibility ensures minimal downtime between projects and reliable operation even in demanding working conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Road Construction Machinery Category

Catonic Sprayer

Price 350000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel body with plastic tank

Cooling System : Other, Air Cooled

Computerized : No

Automatic Grade : SemiAutomatic

Drum Mix Plant

Material : Mild Steel

Cooling System : Other, Water Cooled

Computerized : Yes

Automatic Grade : Automatic

Automatic Mastic Asphalt Cooker Machine

Price 350000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Cooling System : Human Machine Interface

Computerized : Yes

Automatic Grade : SemiAutomatic

Asphalt Mixing Plant

Price 350000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Iron

Cooling System : Frequency Speed Control

Computerized : No

Automatic Grade : Manual

Send Inquiry

Send Inquiry